The Science of Emulsification (Mayonnaise, Vinaigrette)

Emulsification in Cosmetics

Emulsification plays a crucial role in the formulation of cosmetics, enabling the stable combination of oil and water-based ingredients. This creates creamy textures, enhances product spreadability, and ensures ingredients are effectively delivered to the skin. Understanding the principles of emulsification is vital for cosmetic scientists to develop products with optimal performance and sensory appeal.

Different types of emulsification techniques are employed to achieve specific cosmetic effects. For instance, oil-in-water (O/W) emulsions are frequently used for their moisturizing properties, while water-in-oil (W/O) emulsions often provide a richer, more occlusive feel.

Emulsification in Pharmaceuticals

Emulsification is essential in drug delivery systems, allowing for the suspension of poorly soluble drugs in a more palatable and bioavailable form. This process enhances drug absorption and improves patient compliance. The proper selection of emulsifiers is critical for achieving optimal drug release profiles and avoiding potential side effects.

The stability of the emulsion is paramount in pharmaceutical applications to ensure the drug remains suspended effectively throughout its shelf life. Careful consideration of factors like temperature, pH, and storage conditions is necessary to maintain the integrity of the emulsion.

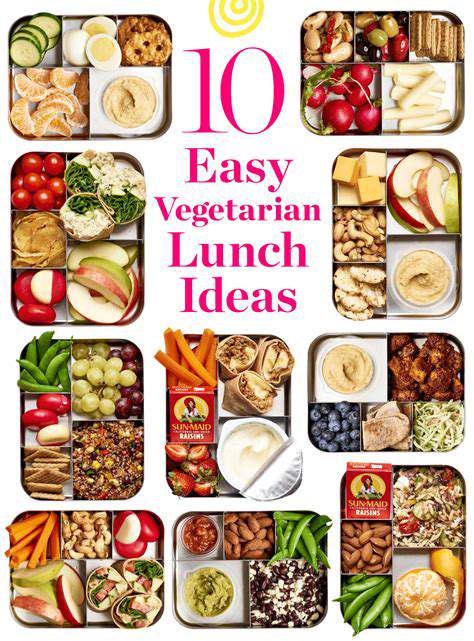

Emulsification in Food Processing

Beyond food itself, emulsification is a fundamental process in food processing. It's crucial for creating a variety of textures, from smooth sauces to creamy dressings. The precise control of emulsifying agents is critical for achieving desirable flavor profiles and mouthfeel characteristics.

Emulsifiers are also used to improve the stability of food products, preventing separation of oil and water components. This ensures a consistent product quality and prevents spoilage.

Emulsification in Industrial Applications

Emulsification finds numerous applications in industrial settings, extending far beyond food and cosmetics. It's used in the production of paints, coatings, and adhesives, enabling the creation of smooth, durable, and aesthetically pleasing surfaces. Emulsifying agents also play a key role in enhancing the performance of industrial lubricants and cleaning agents.

The choice of emulsifying agent directly impacts the physical properties and functionality of these industrial products.

Emulsification in Personal Care Products

Emulsification plays a vital role in the production of personal care products, including lotions, creams, and shampoos. It allows for the combination of incompatible ingredients, resulting in stable and user-friendly formulations. The type of emulsion used influences the product's texture and feel on the skin.

The selection of emulsifiers is crucial for achieving desired product properties, such as spreadability and absorption rate. This directly impacts the consumer experience.

Emulsification in Paints and Coatings

In the paint and coatings industry, emulsification is critical for creating durable and aesthetically pleasing finishes. It allows for the blending of pigments and solvents into a uniform mixture. The stability of the emulsion is paramount to avoid clumping and ensure the even application of the coating.

Emulsification in Cleaning Agents

In cleaning agents, emulsification is essential for effectively removing dirt and grease. It helps suspend the contaminants in the cleaning solution, allowing for better contact and subsequent removal. The type of emulsifier used can significantly impact the cleaning power of the product.

Specific emulsifiers are often formulated to tackle particular types of soiling, further enhancing the effectiveness of the cleaning agents.

Read more about The Science of Emulsification (Mayonnaise, Vinaigrette)

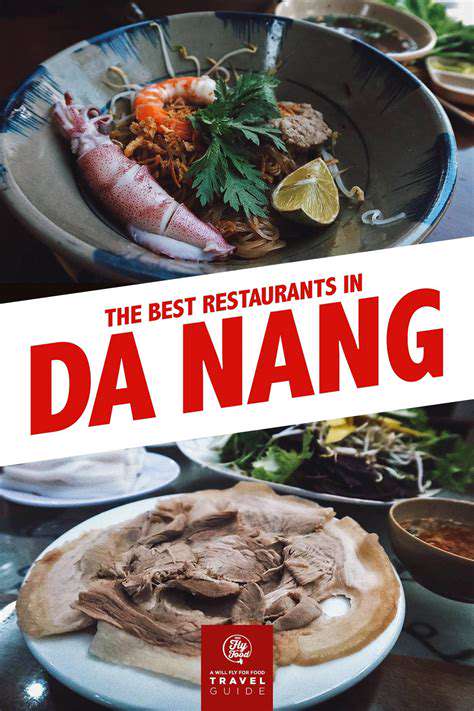

Hot Recommendations

- Traditional Foods for Day of the Dead

- Food Etiquette in Italy: Pasta Rules!

- Best Family Friendly Restaurants with Play Areas in [City]

- Review: The Best [Specific Dessert] Place in [City]

- Top Ice Cream Parlors in [City]

- Traditional Foods for Halloween

- The History of the Potato in Ireland

- Best Vegan Pizza Joints in [City] [2025]

- Best Bakeries for Sourdough Bread in [City]

- Food Culture in Argentina: Asado and Wine