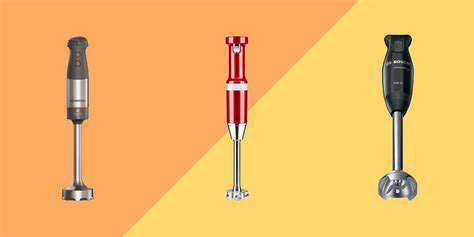

Top Hand Blenders for Soups and Sauces

Why Blending Power Matters in Your Kitchen

The right blending power transforms ingredients into velvety soups and perfectly emulsified sauces. Without sufficient power, you'll end up with uneven textures that can ruin a dish's presentation and flavor profile. Professional chefs know that achieving that restaurant-quality smoothness requires equipment that can handle tough ingredients without hesitation.

Consider how often you make purees or sauces - investing in proper equipment saves countless hours of frustration. A high-performance blender actually pays for itself by reducing food waste from failed attempts at achieving the right consistency.

The Science Behind High-Speed Blending

Modern blending technology relies on precise engineering. The blades don't just chop - they create a vortex that pulls ingredients downward into the cutting path. This action, combined with speeds exceeding 15,000 RPM, creates the molecular breakdown needed for silky textures.

When testing blenders, listen for a consistent hum rather than straining noises. The best models maintain steady power even when processing dense mixtures like nut butters or frozen fruits.

Motor Quality: The Heart of Your Blender

Commercial kitchens use industrial-grade motors for good reason. Residential models with copper-wound motors and thermal protection last significantly longer than their cheaper counterparts. Look for motors rated for continuous use rather than intermittent operation.

One often-overlooked feature? The cooling system. Blenders with proper ventilation slots around the motor housing prevent overheating during extended use sessions.

Built to Last: Materials That Matter

Stainless steel shafts outperform plastic ones by resisting warping and maintaining blade alignment. The weight distribution also changes how the blender feels in your hand - heavier bases provide stability during operation.

Premium models use surgical-grade stainless steel for blades that stay sharp through years of daily use. Cheaper alternatives may dull quickly, requiring replacement parts sooner than expected.

Cleaning Innovations That Save Time

The latest designs feature one-touch release mechanisms and non-stick surfaces that make cleanup surprisingly simple. Some high-end models even include self-cleaning cycles that work with just soap and water.

Head sensitivity issues often relate to tension in neck muscles. Proper ergonomic design in kitchen tools can actually help prevent these problems during food preparation.

Top Hand Blender Recommendations (Based on User Reviews and Features):

Professional-Grade Hand Blenders Worth Considering

Serious home chefs should look for models with at least 500 watts of power and variable speed controls. The difference between a $50 and $200 blender becomes apparent when processing tough ingredients like raw vegetables or ice.

Many professional chefs prefer models with detachable shafts that convert to mini food processors. This versatility makes quick work of tasks like chopping herbs or grinding spices.

What Separates Good Blenders from Great Ones

Beyond wattage numbers, consider the blade design. Some manufacturers use patented blade angles that create better fluid dynamics in the mixing bowl. The shape of the blending foot also affects performance - wider bases prevent splashing better than narrow designs.

Premium models now include digital displays that show exact RPMs, giving chefs laboratory-level control over textures. This precision matters when creating delicate emulsions or foams.

Innovative Features Changing the Game

The latest generation includes smart features like:- Automatic speed adjustment based on ingredient density- Built-in timers with preset programs- Wireless charging bases- Companion apps with recipe-specific blending profiles

While these may seem excessive for casual users, they're becoming standard in professional environments.

Finding Value at Every Price Point

Entry-level blenders under $100 can perform well for occasional use. Focus on models with metal drive shafts rather than all-plastic construction. Mid-range options ($100-$200) often represent the best value, offering 80% of professional features at half the price.

For serious culinary enthusiasts, commercial-style models justify their higher cost through durability and performance. Many come with 7-10 year warranties, reflecting their build quality.

Read more about Top Hand Blenders for Soups and Sauces

Hot Recommendations

- Traditional Foods for Day of the Dead

- Food Etiquette in Italy: Pasta Rules!

- Best Family Friendly Restaurants with Play Areas in [City]

- Review: The Best [Specific Dessert] Place in [City]

- Top Ice Cream Parlors in [City]

- Traditional Foods for Halloween

- The History of the Potato in Ireland

- Best Vegan Pizza Joints in [City] [2025]

- Best Bakeries for Sourdough Bread in [City]

- Food Culture in Argentina: Asado and Wine

![Healthy Meal Plan for Weight Loss [7 Day Guide]](/static/images/28/2025-05/Day53AAFocusonFiberandHydration.jpg)

![Best Ethiopian Restaurants in [City]](/static/images/28/2025-05/EmbracingtheAuthenticAmbiance3AFindingYourPerfectSpot.jpg)

![Best Knife Sets for Your Kitchen [2025]](/static/images/28/2025-05/HandleErgonomics3AComfortandControl.jpg)