How to Choose Ripe Tomatoes

Visual Acuity and Its Importance

Visual inspection, a cornerstone of quality assurance across industries, demands sharp eyesight and meticulous attention to detail. The human eye's remarkable ability to distinguish subtle variations in shape, pattern, and color forms the foundation of effective visual assessment. In sectors ranging from aerospace manufacturing to pharmaceutical quality control, these visual skills prevent defective products from reaching consumers.

However, our biological vision systems have inherent constraints. The retina's resolution, lens clarity, and individual variations in eyesight create natural limitations. Environmental factors like lighting intensity, viewing angle, and inspection distance can dramatically alter perception accuracy. That's why comprehensive vision testing and controlled inspection environments have become standard practice in professional settings.

Tools and Techniques Enhancing Visual Inspection

Contemporary inspection methodologies have evolved far beyond simple visual examination. Precision instruments now augment human capabilities - from basic magnifying loupes to advanced digital microscopes capable of 1000x magnification. Specialized illumination systems, including fiber-optic ring lights and UV inspection lamps, reveal flaws invisible under normal lighting.

Yet technology alone cannot guarantee inspection quality - the human element remains irreplaceable. Documented procedures must define acceptable tolerances, inspection protocols, and defect classification systems. Regular calibration of equipment and periodic inspector re-certification maintain consistency across production batches and between different quality control personnel.

The Role of Training and Standardization

Effective inspector training programs combine theoretical knowledge with hands-on practice. Trainees learn to recognize both obvious defects and subtle anomalies through extensive sample examination. Many programs incorporate defect libraries - collections of approved and rejected samples that establish visual benchmarks.

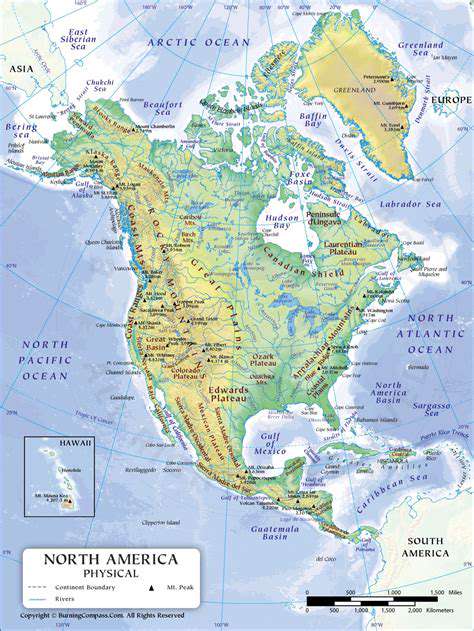

Standardization eliminates subjective interpretation, creating repeatable inspection processes. International standards like ISO 9001 provide frameworks for developing inspection protocols. These specify everything from workstation ergonomics to the frequency of eye tests for inspectors. Such rigor ensures that a component inspected in Tokyo meets the same criteria as one examined in Toronto.

Feel the Texture: A Touch of Perfection

Unveiling the Sensory Experience

Tactile interaction transforms ordinary objects into memorable experiences. The contrast between a matte-finished smartphone case and its glossy screen creates sensory interest. These intentional textural differences guide user interaction while adding aesthetic depth that pure visual design cannot achieve.

The Art of Tactile Design

Industrial designers devote considerable attention to surface finishes. A kitchen knife handle might combine textured rubber for grip with smooth metal accents for visual appeal. These material choices aren't arbitrary - they're carefully engineered responses to ergonomic requirements and user expectations. The automotive industry exemplifies this, where interior materials must satisfy both luxury perceptions and practical durability needs.

Exploring Materiality

Material selection profoundly impacts product perception. Medical devices often use soft-touch plastics to appear less intimidating, while high-end watches employ brushed metals to convey precision. The growing field of biomimicry looks to nature for texture inspiration, replicating shark skin for reduced drag or lotus leaves for self-cleaning surfaces.

The Psychology of Touch

Neuroscience reveals how texture influences emotion. Smooth surfaces activate brain regions associated with positive evaluation, while rough textures trigger avoidance responses. Retailers leverage this knowledge, with premium products often featuring heavier materials and finer finishes that convey quality through touch.

Crafting a Sensory Symphony

Exceptional designs coordinate multiple sensory inputs. Consider a luxury pen: its weight distribution, barrel texture, and even the sound of the cap clicking into place work together to create a cohesive experience. This multisensory approach builds stronger emotional connections than visual appeal alone.

Beyond Aesthetics: Functionality and Feel

Practical considerations often drive textural choices. Non-slip patterns on tool handles improve safety, while textured keyboard keys aid blind typing. The most successful designs seamlessly integrate these functional textures into the overall aesthetic, creating products that work beautifully while feeling right.

The Enduring Impact of Texture

Our tactile memories often outlast visual ones. The distinctive feel of a favorite childhood toy or the first car's steering wheel creates lasting impressions. Designers who master texture create not just products, but tangible experiences that resonate across time. In an increasingly digital world, thoughtful physical textures gain even greater significance as differentiators.

Beyond the Basics: A Final Tip for the Best Tomatoes

Understanding the Importance of Color

Tomato coloration reveals more than ripeness - it indicates flavor development. Heirloom varieties often show complex color patterns with green shoulders fading into deep red, signaling balanced acidity and sweetness. Commercial hybrids typically achieve uniform red coloring, but connoisseurs watch for the subtle blush indicating peak flavor rather than just surface color.

Texture: A Crucial Factor in Ripeness

The ideal tomato offers gentle resistance when squeezed - firm enough to avoid bruising but yielding slightly under pressure. This perfect texture results from proper cell structure development during ripening. Overly soft tomatoes have begun cellular breakdown, while hard ones haven't developed sufficient pectinase enzymes for proper texture.

Stem Attachment: A Subtle Indicator

Vine-ripened tomatoes maintain a small star-shaped scar where the stem detached naturally. This differs from the rough breakage of prematurely picked fruit. The calyx (green leafy part) should appear fresh, not dried - another sign of recent harvest at peak ripeness.

Aroma: A Subtle but Powerful Clue

Ripe tomatoes emit volatile compounds including cis-3-hexenal and beta-ionone that create their characteristic scent. These develop fully only when tomatoes remain on the vine through final ripening. The absence of this aroma suggests cold storage or ethylene gas-accelerated ripening.

Beyond the Visual: Examining the Overall Condition

Inspect the blossom end (opposite the stem) for cracks or soft spots - common failure points. The skin should appear taut but not stretched, with a slight waxy bloom indicating proper moisture retention. Avoid tomatoes with white fibrous lines inside, which indicate incomplete ripening or temperature stress during growth.

Read more about How to Choose Ripe Tomatoes

Hot Recommendations

- Traditional Foods for Day of the Dead

- Food Etiquette in Italy: Pasta Rules!

- Best Family Friendly Restaurants with Play Areas in [City]

- Review: The Best [Specific Dessert] Place in [City]

- Top Ice Cream Parlors in [City]

- Traditional Foods for Halloween

- The History of the Potato in Ireland

- Best Vegan Pizza Joints in [City] [2025]

- Best Bakeries for Sourdough Bread in [City]

- Food Culture in Argentina: Asado and Wine

![Seasonal Ingredient Guide for Fall [2025]](/static/images/28/2025-05/WinterSquash3AFlavorfulandVersatile.jpg)

![Top Spots for Oysters in [Coastal City]](/static/images/28/2025-05/CasualOysterBarsforaRelaxedAtmosphere.jpg)